ProLean Help on Line

Pro.Lean is an add-in for Movicon NExT which allows users to create and manage master data and indicators for analysing production performances in the manufacturing sector. Pro.Lean provides the connection to the field devices to collect data (counters, states and events), aggregate and historicize them in the database. These data are then the objective basis on which Pro.Lean calculates the key performance indicators (KPI) on which users can perform an analysis on inefficiencies and downtimes. In fact, by using the web-based standard reports of Pro.Lean, users can analyse and visualize KPIs for each machine, job and shift. This provides plant personnel with the advantage of having a powerful tool to perform detailed analysis to monitor availability, productivity and quality, which are the three main components that constitute the OEE (Overall Equipment Efficiency) index.

Pro.Lean is a “Manufacturing intelligence” solution, which is equipment-centric based. Each production machine connected to the system populates the Pro.Lean database with detailed data that entail the number of pieces produced and production events. These data are then contextualized according to the master data present in the database and made available for analysis through standard reports and Movicon NExT.

To ensure that companies can actually learn and improve their production performance, it is necessary to implement a system that collects, aggregates and contextualizes production information. This is the main task of a Manufacturing Intelligence solution, such as Pro.Lean.

Its purpose is to help plant operators to answer the fundamental questions: "How much is my system producing and how is it performing?", "Why can't I reach full performance capacity?".

Pro.Lean not only provides the answers to these questions, but allows the sharing of strategic KPI parameters "on-the-fly" across the enterprise organization.

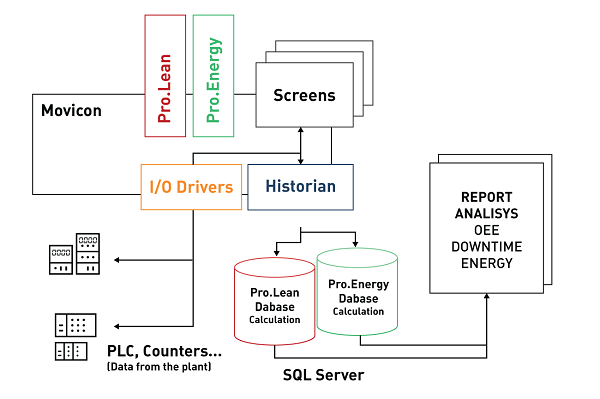

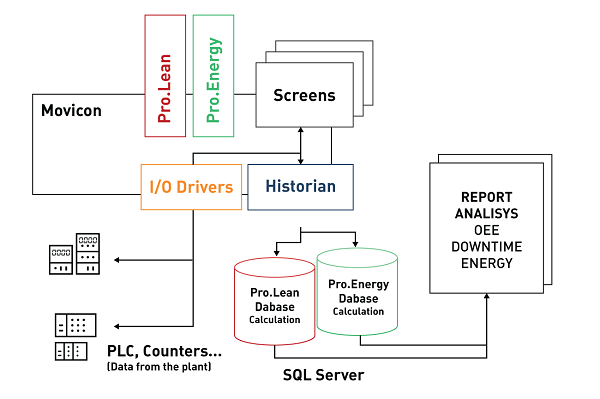

The following image illustrates the architecture and concepts which Pro.Lean is based on:

Picture 1 – Overall Pro.Lean structure

Movicon NExT interfaces field devices (PLCs and machine control systems) to provide values of counters, states and machine events that are manipulated in the database in order to calculate efficiency metrics.

The configuration wizard creates and manages the master data which is needed to calculate performances (i.e. units of measure, manufacturing machines), as well as associating field variables (Movicon NExT Tags), and creates data loggers to historicise data in the database: units of measure, work shifts, recipes (production recipes processed by the machines) and downtime causes.

Movicon NExT collects raw data from the field and records them in the Pro.Lean SQL Server database which is shared with factory personnel in standard report format (developed using Movicon.NExT).

In addition, Movicon NExT creates graphical screen dashboards on board the machine which display realtime data. The data contained in these dashboards comes from database views that contain data relating to counters, time, productivity and KPI, for the production currently running in the shift, with individual screens dedicated for each production resource managed by the system.

Intended audience

This manual contains a description of the Pro.Lean add-in module for Movicon NExT including the configuration wizard, the SQL database and the standard reports.

It is inteneded for those who are responsible for configuring and maintaining master production master, and system integrators who want to provide to their customers a tool for analysing performance metrics and production data.

This document does not cover installation and operation of Movicon NExT or how to connect to the individual field devices via I/O Drivers and OPC technology.